exceeding expectations since 1972

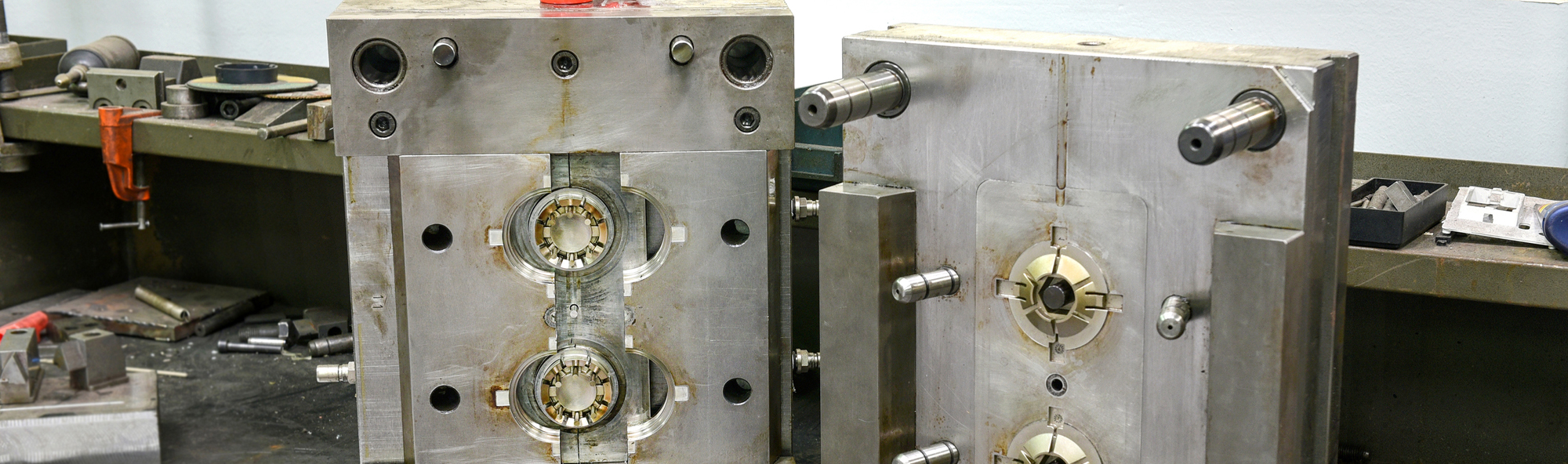

B&H Pattern Inc. is a manufacturing facility producing foundry tooling and casting related products. Patterns, coreboxes, core setting fixtures, permanent molds, assembly fixtures and reverse engineering. B&H Pattern is on the leading edge of simple to complex pattern and tooling design. Multiple software packages available.

READ WHAT OUR HAPPY CUSTOMERS ARE SAYING…

Gary B.

In times of the covid pandemic this company managed to keep devoted employees employed while securing jobs for the future. The quality employees dedicated more effort to ensure the molds and patterns going to customers were fine tuned with quality and precision.